Barry's Coilguns

Mark 1

- Introduction

- Photos

- Launch Speed

- Oscillator

- Coil Timer

- Trigger Logic

- Coil Driver

- Power Supply

- Winding Coils

- Tube Size

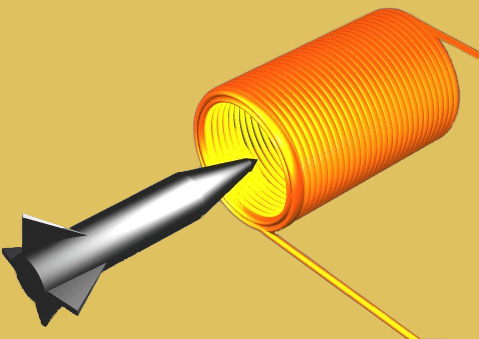

- Projectile

- Breadboard

- Measuring Coil

- Max Coil Strength

- Computing Coil Timing

- Mark 1 Results

Computing Maximum Coil Strength

But what about coil forces of greater than one gee? All the measurements were taken with local gravity of exactly 1-gee at low current, but we want to know the maximum force at full current.

Air Core Coils

One really nice property of air-filled coils is their linearity. (Another nice property is that it's really cheap to fill a coil with air.) The coil's force is exactly proportional to the voltage (really the current) applied.

We assume the coil's resistance is constant (we're neglecting heating effects) and the steel in the screw is not saturated by the magnetic field. So the attractive force on the screw is a simple multiple of the measured one-gee force as you increase the power supply. If you triple the supplied voltage, you triple the coil's force.

The maximum coil strength corresponds to the maximum voltage (i.e. current) you're able and willing to supply. The "maximum" current or voltage might be limited by the capability of your power supply. Or it might be limited by the amount of heat you can dissipate in the coil. Or it might be limited by your desired peak force. Whatever. Just choose your own maximum voltage, use it as a starting point and see what happens. You can later scale it according to your needs.

Actually, this is an extremely important design point. What maximum current density will you choose in the coil wires? This choice will govern most of your subsequent design parameters such as wire size, number of turns, coil resistance and the power supply voltage and current requirements.

You should check with a wire manufacturer to choose your maximum current density. For example, a company such as WireTron (www.wiretron.com) has free software you can quickly download with tons of information about magnet wires. (Try it, the software is great!) Please tell me about it if you have other ways of calculating safe current density in coil wires.

Spreadsheet Calculations

Start your spreadsheet with two columns for your measurements. One column is "height above the table", and one column for the "applied voltage for one-gee force". Enter all your numbers into this table. I measured heights in 1-mm increments from 38mm down to 0mm. The voltage will vary for particular screws and coils, but my voltage measurements ranged from 12vdc down to 1.8vdc.

Add two columns for calculations. One column will be "depth into coil" and one column will be "force at maximum voltage". They are:

depth into coil = di = Lscrew - heighti

force at max voltage = Fmaxi = Vmax / Vi

Note that positive values of di indicate the projectile is partly inside the coil, and negative values of di are before the projectile has entered the coil.

Now your spreadsheet contains some useful information, and looks something like mine:

| Vmax | 12.5 | volts | |

| Lscrew | 31.6 | mm | |

| Amax | 2.5 | amps | |

| Measurements | Calculations | ||

| (mm) | (volts) | (G) | (mm) |

| height | Force 1G | Fmax | Depth |

| 38 | >12.5 | -6.4 | |

| 37 | >12.5 | -5.4 | |

| 36 | 12 | 1.04 | -4.4 |

| 35 | 9.8 | 1.28 | -3.4 |

| 34 | 8.1 | 1.54 | -2.4 |

| 33 | 6.7 | 1.87 | -1.4 |

| 32 | 5.7 | 2.19 | -0.4 |

| 31 | 5.2 | 2.40 | 0.6 |

| 30 | 4.6 | 2.72 | 1.6 |

| 29 | 4.2 | 2.98 | 2.6 |

| 28 | 4.05 | 3.09 | 3.6 |

| 27 | 3.6 | 3.47 | 4.6 |

| 26 | 3.3 | 3.79 | 5.6 |

| 25 | 2.9 | 4.31 | 6.6 |

| 24 | 2.8 | 4.46 | 7.6 |

| 23 | 2.5 | 5.00 | 8.6 |

| 22 | 2.3 | 5.43 | 9.6 |

| 21 | 2.35 | 5.32 | 10.6 |

| 20 | 2.2 | 5.68 | 11.6 |

| 19 | 2 | 6.25 | 12.6 |

| 18 | 2 | 6.25 | 13.6 |

| 17 | 2.05 | 6.10 | 14.6 |

| 16 | 2 | 6.25 | 15.6 |

| 15 | 1.95 | 6.41 | 16.6 |

| 14 | 1.92 | 6.51 | 17.6 |

| 13 | 1.85 | 6.76 | 18.6 |

| 12 | 1.87 | 6.68 | 19.6 |

| 11 | 1.9 | 6.58 | 20.6 |

| 10 | 1.9 | 6.58 | 21.6 |

| 9 | 1.9 | 6.58 | 22.6 |

| 8 | 1.9 | 6.58 | 23.6 |

| 7 | 1.84 | 6.79 | 24.6 |

| 6 | 1.85 | 6.76 | 25.6 |

| 5 | 2 | 6.25 | 26.6 |

| 4 | 2.1 | 5.95 | 27.6 |

| 3 | 2.12 | 5.90 | 28.6 |

| 2 | 2.35 | 5.32 | 29.6 |

| 1 | 2.5 | 5.00 | 30.6 |

| 0 | 2.5 | 5.00 | 31.6 |

| -1 | 2.8 | 4.46 | 32.6 |

| -2 | 3.1 | 4.03 | 33.6 |

| -3 | 4.5 | 2.78 | 34.6 |

Now create a graph of Fmax vs Depth, and you get a chart simply full of nift:

Conclusions

This shows the force is small when the projectile is outside the coil. For a good launch from a standstill, you want to have high acceleration. Since it's moving relatively slowly here, you want to get it moving quickly to avoid slight irregularities that will cause timing problems later. So you should have the projectile begin partly inside the coil, and use a mounting system that position the projectile in exactly the same spot.

If the projectile overshoots the "sweet spot" (because your timing circuit is not perfect) then acceleration drops off rapidly.

There's probably a lot more to say here, but more things will be evident in spreadsheet #3. That's where we calculate the actual projectile speed down the barrel, and from that we get the coil timing requirements.

| < Previous | Page 14 of 16 | Next > |

©1998-2026 Barry Hansen