Barry's Coilguns

Mark 5

- Introduction

- Contactor

- Capacitors

- Bus Bar

- Control Panel

- Buying Parts

- Cart

- Spark Gap

Barry's Coilgun Mark V

This somewhat larger single-stage coilgun will examine two key concepts:

- The high-power switch is a mechanical contactor of a novel design.

The large copper contacts offers an ESR (equivalent series resistance) much lower than silicon devices.

The problems we face are contact bounce and wear.

The wedge or arrowhead shape switch described here might solve all the difficulties.

- The coil and a large projectile are jointly designed for low flux density. For maximum efficiency, we limit flux density to 1 Tesla or less. This will likely result in a very large and heavy projectile with low velocities. But the high efficiency results in very high kinetic energy!

Background

The most common mechanical switches for coilguns are

- Light switch - extremely cheap but low power (example 1 and example 2)

- Mechanical contactor - an electromechanical relay (example 3 and example 4)

- Triggered spark gap - for voltages greater than 1KV, noisy loud and scarey

- Metal plates - large copper surface area, slam together with a spring or hammer (example 6)

These designs generally suffer from slow closure time and arcing. The contact bounce is classically on the order of 5 - 20 milliseconds, which is comparable to the entire launch pulse.

I'm testing a mechanical design that avoids these problems.

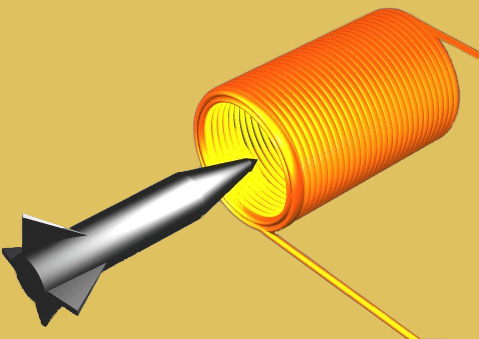

Wedge Contactor Concept

Push a wedge-shaped copper contactor into a matching wedge receptacle at moderately high speed.

This illustration shows one possible solenoid-operated design.

Push a wedge-shaped copper contactor into a matching wedge receptacle at moderately high speed.

This illustration shows one possible solenoid-operated design.

The wedge or "arrowhead" shape has a narrow angle. This causes large compressive forces for good contact without relying on springs or external pressure.

At a certain critical angle (around 8 degrees for copper) the wedge will "stick" or lock in place, and needs no other mechanism to maintain contact.

The copper wedge completes the connection between the two sides of the receptacle. Any slight misalignment on entry will not complete the connection; it only conducts when it's touching both sides of the solid mounting blocks.

The wedge itself does not have or need any connecting wires. It merely connects the two copper blocks together.

The copper wedge moves at a sufficient speed to reduce contact bounce and, in conjunction with the shape and solid blocks, does not have the springiness of leaf-type relays and switches.

The nature of an inductive circuit is such that current does not immediately flow. There will be a short amount of time as current builds up according to the LC time constant. This provides some time for the contacts to finish closing before arcing can occur. If the closure is completed quickly enough there will be no sparks or contact wear.

| < Previous | Page 1 of 8 | Next > |

©1998-2026 Barry Hansen