Barry's Coilguns

Coilgun Mark 2

- Introduction

- Hints and Suggestions

- RLC Simulation

- RLC Analysis

- LC Time Sim

- Inductor Sim

- Wire Loop

- Java

- Photographs

- Schematic

- SCR

- Construction

- Result: Position

- Result: Turns

- Result: Length

- Result: Iron

- Result: Tube

- Result: Voltage

Hints and Suggestions

Here is a list of random suggestions for a single-coil capacitive-discharge coilgun.

Please note your mileage may vary. You should evaluate everything carefully before using a suggestion! Coilguns are an infant science, and there are many unknowns. Use safety precautions!

High-Level Overview

- Use a single stage. One coil. That's it. All timing is controlled by the LC time constant.

- A useful operating region is in the 450-600 vdc range, 2200 microfarad capacitors, and "hockey puck" SCRs'.

- It is easy to build coilguns that work. It is hard to build coilguns that work well.

- Your goal should be to provide only the amount of energy in only the duration of time the projectile can absorb it.

- Coilguns are inherently inefficient. Most mechanical means of shooting small iron projectiles are better than coilguns in almost every way. For example, a cheap Daisy BB gun is far easier to use and shoots better than my coilgun ever will. And gunpowder technology is vastly more powerful. Still, an electromagnet launcher is a much cooler concept than low-tech expanding gases!

- Why do I think coilguns are so inefficient? Because they inherently have a long "air gap" down the middle of the firing tube. It builds in a relatively huge amount of magnetic reluctance in the magnetic circuit. Where linear and circular motors deal with 1mm or less of air gap between parts, we have to start with 1-inch or more air gap. We just can't get comparable efficiency until our "air gap" in the tube is reduced to a similar figure.

- I don't have a good design (yet!) for sensing position of the projectile. If I did, I wouldn't have gone to all the trouble of designing my open-loop timing circuits in the Mark I.

- Pay attention in your EE Power class in college. You never know when it's going to come in handy.

- Buy old EE books at used-book stores. Don't bother looking for useful books in a college bookstore. There are exactly zero books written in the last twenty years that have anything original regarding basic coil design.

- If you trace any EE book's bibliography back, they always refer to "The Magnetic Circuit" by V.Karapetoff, circa 1905. Haven't found one yet in the used bookstores. Still looking.

- Build two coilguns, and have a shoot-off with yourself. Just don't get caught in the crossfire.

Power Supply

- Power? The easiest to build is a simple transformer and a single diode rectifier.

- More portable to use two 1.5v batteries to drive an old camera flash unit charger to generate about 450v.

- You could use up a lot of batteries, so you might try a plug-in 3v battery eliminator instead.

- You can build voltage inverter circuits that convert low voltage dc (eg batteries) into high voltage dc for charging capacitors. These circuits can supply higher charging current to the capacitors. Look in the ARRL Radio Amateur's Handbook for a number of good high voltage power supply circuits.

- Power output stage to drive the coil: An FET with a low-resistance "on" would work great in this instance. And it takes very little power to drive it, so it could be connected directly to cmos logic if desired. A good one would be the TIP 142 or TIP 147.

- Power output stage with an SCR will be simplest, easiest and cheapest.

- Power output "stage" of just a mechanical switch would work, but it will arc over and weld itself shut at higher currents.

Capacitor

- When the accelerating energy is present for longer periods of time, the current carrying capacity of the components drops way off.

- Use a capacitor rated for 25% more than your working voltage, then you don't have to worry about arcing, leaking, or blowing up.

- Use a capacitor rated for 500v or more, with as much capacitance as you can find.

- Should get 25 uf (microfarad) at least, larger if you can. It could cost $5 to $20 or maybe even more.

- Pick a fixed capacitor, and tune your coilgun by varying the number of turns in the coil.

Coil

- Use real magnet wire, not bell wire or hookup wire. You'll get a lot more turns into a smaller space.

- Tightly wound coils are a worthy task. Tape or glue or epoxy all layers to prevent movement. Keep in mind that some glues can damage enamel on coil wire.

- Glyptol (or glyptal). The larger paint stores have have it. Ones that carry automotive paints maybe.

- Glyptol is tough to get off your fingers. Use lots of linseed oil. Even the boiled type is slow drying, but it penetrates rust and crystalizes, like amber.

- There also is square cross section wire available, but at a price.

- Toroid: A coil wound on a toroid has little or no external magnetic field. All the magnetism induced by the coil just travels in circles around and around the toroid. None of it comes out. The magnetic field lines can complete their loop thousands of times easier by going through the toroid's material than by going through the air around it. So they never reach the projectile. So toroids would be your last choice in designing coilguns. Other than that, they would look pretty cool. Not work so good, though.

- Always use a coil protection diode to dissipate stored energy. This will save your switches and SCR's. Not to mention your bacon.

- The amp-turns output of a coil is independent of wire size, for a fixed voltage source and a fixed-volume coil. That is, the resistance varies inversely to the number of turns. The product is constant.

- Wire size of 18ga has lower inductance than 24ga for a fixed-volume coil. Since lower inductance is usually better (it speeds up the time needed to establish the magnetic field), make your first coils with the larger wire sizes.

- Larger gauge wire cuts down on resistance (and inductance and impedence) ....hence HUGE currents... it's almost like shorting the caps across themselves but for a short time.

- Really large wire is more like plumbing, less like wiring.

- You can wind coils by mounting your coil form on a lathe, and turning the stock by hand.

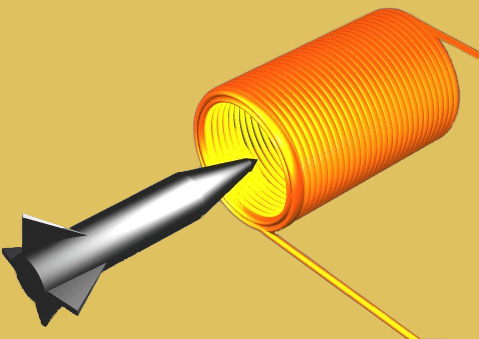

- You can substantially increase the flux by decreasing the air gap. There are at least three

ways to do this.

- The first way is to use large diameter iron washers at both ends of your coils. The washers should be thick enough not to saturate, and have a much larger diameter than the coil. The washers help conduct the otherwise air fringing flux outside the coil.

- The second way is a variant of the first. Use the washers, but split in half lengthwise a section of iron pipe with an interior diameter larger than the coil. Assemble these with the washers into an iron shell around the coil. The air gap is still dominated by the gap to the projectile, but is much lower reluctance than it would otherwise be.

- The third way is a variant of the other two, and very hard to construct. What you really want is an iron shell that is radially laminated from thin sheets of iron. This is almost impossible to construct, but you can approximate it by making a central plastic dummy coil with dimensions larger than your coil. Onto this you wind a layer of soft iron wire along the axis of the cylinder and radially around the dummy cylinder. Once you have a neat layer, you epoxy the iron wire shell, and wind another layer. Epoxy that as well, then cut away the center of the ends of the iron wire shell - very difficult, I grant you - so that the iron wire shell could be made to slip over your bore tube. You may want more layers of iron wire to get the cross sectional area up to avoid saturation, just do the winding carefully and epoxy each layer till you get what you want. All of these methods will increase the inductance of the coil, so you may need to back the turns down and increase the wire size, all of which are advantages, I think.

Tuning the Coil

- The coil inductance has the most effect on success. The coil inductance can change duration of pulse and peak energy.

- Buy an inductance meter for sorting coils and measuring effect on acceleration.

- Your first coil should be built with a small number of turns and picking a fixed capacitance and dc charging source.

- The first attempt should have so few windings that the pulse is completely gone before the projectile exits coil.

- Continue to add windings until maximum exit velocity occurs.

- For multi-coil guns, the next coil will have less time to impart energy. This is countered by decreasing coil inductance to shorten duration.

- The law of diminishing returns on coil numbers applies here. Once ideal inductance and capacitance values are achieved, varying voltage can adjust for elevation or slight differences in projectile mass.

- An alternative to adjusting inductance is to tinker with capacitors. Make one big honking coil, and get a supply of caps from 1000 - 2500uf. Hook them up in a combination of series and parallel until you get maximum velocity from the gun.

- Avoid saturation - it wastes energy. It is easier to fall prey here than one thinks when playing with the larger values (eg. 2000 microfarads @ 450 vdc).

- The best coil length is 33% longer than the projectile. This has maximum efficiency.

- Minimize the coil's effect of pulling the accelerated projectile back as it exits coil.

- The two obvious ways to fight this are to further reduce effective time of exposure to deceleration forces or increasing projectile length.

Firing Tube

- Tube wall should be as thin as practical to allow minimal distance between inside diameter (ID) of coil and outside diameter (OD) of projectile.

- Non-conductive tubing (paper, plastic or glass) will be much better yet, because it won't waste any energy in eddy currents while the magnetic field is turned on.

- A plastic drinking straw can work. It has the advantage of allowing optodetectors to see through the straw without cutting holes in it. Mechanical rigidity is actually provided by the coils.

- Ideal projectile shape varies between cylinder and tube shaped. Tube shape and rolled cylinder has my attention.

- Careful about duty cycle and heat buildup. Traditional motor design at 100% duty cycle says to make all coils less than 2 inches thick, or it will overheat.

Computer Modelling

- Computer modelling is a great way to lose lots of sleep.

- But I'm going to try it anyway. (See FEMM Modelling chapter.)

- Take into account the coil's inductance depends greatly on how far the projectile has entered the coil.

- Where air is in the magnetic circuit, everything depends so much on fringe effects. To calculate fringing as the flux enters/exits the projectile's material, you need some kind of finite-element analysis tool. Look in Yahoo:Science:Physics:Magnetism to see what tools and formulas are available.

Most coilgun web sites are photographs and some schematics, but not much design info. What we really want to know is: how many turns, what wire size, how much capacitance, what voltage, what projectile, what exit speed?

I hope I've given you some good ideas, sparked some questions, and perhaps saved you from making mistakes. Let me know what works for you!

Thanks to RG for letting me plagerize his descriptions of enclosing coils in iron to increase the magnetic field!

| < Previous | Page 2 of 18 | Next > |

©1998-2026 Barry Hansen