Practical Coilgun Design

Theory

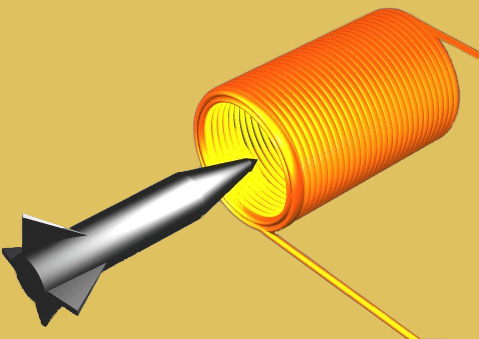

- Introduction

- Number of Turns

- Magnet Wire

- Coil Size

- Wire Size

- External Iron

- Wire Loop

- Control

- Phototransistors

- Coil Length

- Number of Coils

Magnet Wire

What kind of wire do you use in electromagnets?

Magnet Wire

You should use magnet wire. Duh. This is copper or aluminum wire with a thin insulation

to prevent short circuits. It is single-strand wire insulated with enamel, varnish, cotton, glass,

asbestos or some combination of these. To meet the immense variety of uses and to gain competitive

advantage, a great number of kinds of enamel and of fiber insulations have been developed and

are widely available.

You should use magnet wire. Duh. This is copper or aluminum wire with a thin insulation

to prevent short circuits. It is single-strand wire insulated with enamel, varnish, cotton, glass,

asbestos or some combination of these. To meet the immense variety of uses and to gain competitive

advantage, a great number of kinds of enamel and of fiber insulations have been developed and

are widely available.

"The Institute of Electrical and Electronics Engineers (IEEE) thermal classes of insulation, defined by upper temperature limits at which the untreated insulation will have a life expectancy of at least 20,000 hours, are

- O for 176F (80C)

- A for 221F (105C)

- B for 266F (130C)

- F for 311F (155C)

- H for 356F (180C)

In general, materials such as cotton, paper, and silk are class O. Organic materials, such as oleoresinous and Formvar enamels, varnish-treated cotton, paper, and silk are class A. Asbestos, mica, silicone varnishes, and polyamide are class H, while various synthetic enamels fall in the B and F classes. The polyesterimide enamels, however, are capable of withstanding temperatures of 356-392F (180-200C).

Almost all magnet wire is insulated soft-drawn electrolytic copper, but aluminum is being used more, especially in times when copper is scarce or high-priced and where space is not limiting. Round aluminum wire, being soft, flattens under pressure giving a higher space factor in coils than might otherwise be expected. At temperatures above 392F (200C) copper oxidizes rapidly; it also becomes brittle when under stress at such temperatures. Its high-temperature strength is increased considerably by adding a small amount of silver (about 30 oz/ton or 1kg/metric ton). Anodized aluminum is preferred for higher temperatures, up to 572F (300C) or more, while copper nickel wire with an anodized aluminum coating may be operated at still higher temperatures."

Source: "McGraw-Hill Encyclopedia of Science & Technology", Vol. 10 LEP-MES, 8th Edition, (c) 1997, ISBN 9-07-911504-7 (set)

Wire Gauges are Logarithmic

If you have a wire size in mind and need to estimate another size, note that AWG (and SWG) size scale is based on the cross-sectional area (circular mils) and hence is a logarithmic scale. Each 3-gauge step in size corresponds to a doubling or halving of the cross sectional area.

So, one simple result of this is that if you take two strands the same gauge, it's the equivalent of a single wire that's 3 gauges lower. So two 20 gauge strands is equivaent to one 17 gauge wire.

Solid wire diameters increases (or decreases) by:

- factor of 2 every 6 gauges

- factor of 3 every 10 gauges

- factor of 4 every 12 gauges

- factor of 5 every 14 gauges

- factor of 10 every 20 gauges

- factor of 100 every 40 gauges

If you are more interested in current-carrying ability than physical size, then remember that a change of 3 AWG numbers equals a doubling (or halving) of the circular mils (the cross sectional area). Thus, if 10 AWG is safe for 30 amps, then 13 AWG is okay for 15 amps and 16 AWG is good for 7.5 amps.

Source: www.epanorama.net/documents/wiring/wire_resistance.html

Current ratings

Most current ratings for wires (except magnet wires) are based on permissible voltage drop, not temperature rise. For coilguns we usually choose wire sizes that will greatly exceed the "current rating" for its size. The most relevant figure would be its fuse rating or short-circuit current.

For example, 0.5 mm^2 wire is rated at 3A in some applications but will carry over 8 A in free air without overheating. You will find tables of permitted maximum current in national electrical codes, but these are based on voltage drop (not the heating which is no problem in the current rating those codes give).

Some typical current ratings are:

| A/mm2 | R/mohm/m | I/A |

|---|---|---|

| 6 | 3.0 | 55 |

| 10 | 1.8 | 76 |

| 16 | 1.1 | 105 |

| 25 | 0.73 | 140 |

| 35 | 0.52 | 173 |

| 50 | 0.38 | 205 |

| 70 | 0.27 | 265 |

Wire Sizes used in Fuses

The Standard Handbook for Electrical Engineers lists the following formula:

33 * (I/A)^2 * S = log( (Tm - Ta) / (234 + Ta) + 1 )

- I = current in Amperes

- A = area of wire in circ. mils

- S = time the current flows in seconds

- Tm = melting point, C (copper's melting point is 1083 C)

- Ta = ambient temp, C

Wire Guide

Visit one of the major wire manufacturers, WireTron, at www.wiretron.com for free software that provides lots of information about (what else?) wires. It can help you select and understand size, material, strength, resistance, maximum current, weight, insulation and other factors.

| < Previous | Page 3 of 11 | Next > |

©1998-2026 Barry Hansen